Sometimes, when you’re dealing with industrial equipment, you come across terms that sound confusing and overly technical. If you’ve ever stumbled upon the phrase eccentric hemispherical valve, you might have wondered what it actually means and why it’s important. Perhaps you’re trying to determine how it works, whether it’s worth using, or how it compares to other types of valves. That uncertainty can be frustrating when all you want is a clear, straightforward answer.

In this post, we’ll break down what an eccentric hemispherical valve is, how it works, and why industries rely on it. You’ll find simple explanations, practical examples, and insights that cut through the jargon. By the end, you’ll understand not only what this valve does but also when and why it’s the right choice. Let’s dive in and make sense of it together.

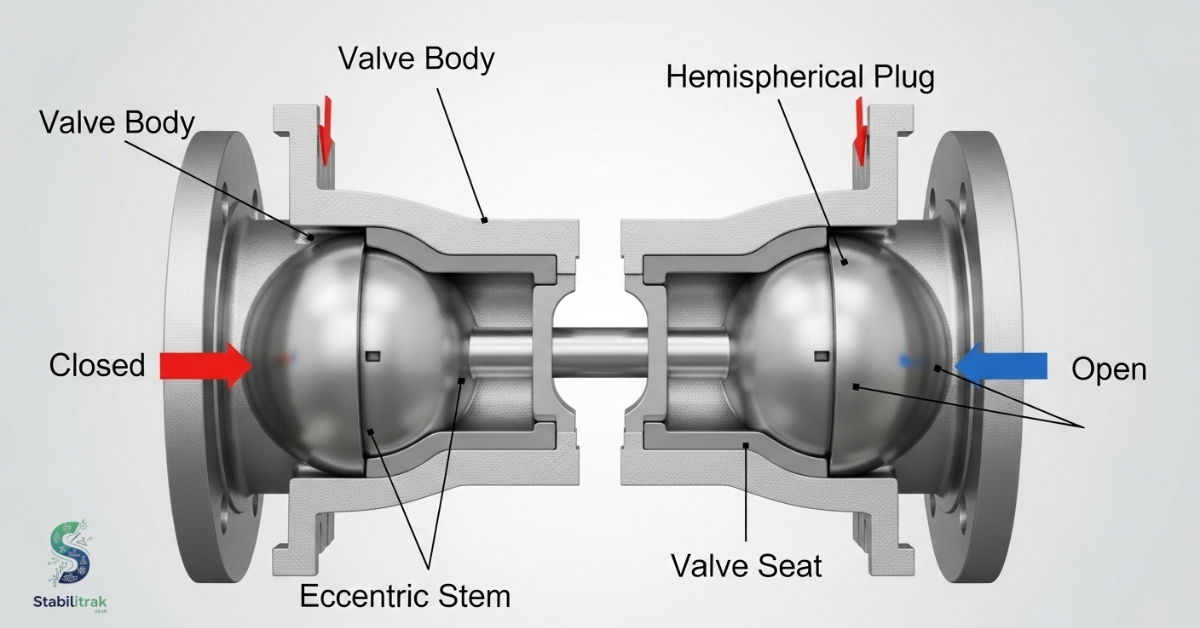

Design Basics & Key Components

At its core, an eccentric hemispherical valve features a hemispherical disc (or semi-ball) mounted on an eccentric axis, meaning it’s offset from the centerline of the valve body. As the valve opens, the disc lifts slightly off the seat, then rotates away, reducing friction. When closing, that motion reverses, and the disc seals only at the final moment. That design significantly reduces wear on the sealing surfaces.

Important components include the valve body, valve seat, hemispherical disc, stem, and actuator (manual, electric, pneumatic). Materials like stainless steel, alloy steel, or hard-faced materials (e.g., tungsten carbide) are often chosen for seats to resist abrasion. The stem must transmit torque cleanly and handle corrosion.

Read More Article: How Much Does a Tooth Crown Cost?

How Eccentric Hemispherical Valves Operate

Operation is usually via a quarter-turn mechanism. When closed, the disc is pressed against the seat, giving a near leak-proof seal. To open: first lift (via eccentric offset), then rotate fully; fluid then flows through a relatively unobstructed path, which reduces pressure drop and turbulence, valuable when you’re handling slurry or media with solid content.

When closing, you reverse the motion: rotate back, then drop the disc into contact with the seat. Because contact until that final moment is minimHow Eccentric Hemispherical Valves Operateized, there’s far less wear and corrosion, a huge win when you have high abrasion or harsh chemicals.

Major Advantages

- Reduced wear and longer life: Eccentric lifting avoids constant scraping of the seat, so sealing surfaces last much longer.

- Low operating torque: Since full contact happens only in sealing, you don’t need a huge force or big actuators as with gate or full ball valves.

- High sealing reliability / zero leakage: Precision machining + tight seat match + good materials can give metal-to-metal sealing that maintains integrity under high pressure.

- Better flow efficiency: With straight‐through or nearly straight flow paths when open, pressure losses are smaller, good for viscous fluids or when flow rate matters.

- Wide material and design variation: Top-mounted or side-mounted actuators, soft or metal seats, double eccentric versions, etc., make this valve usable in many industrial settings.

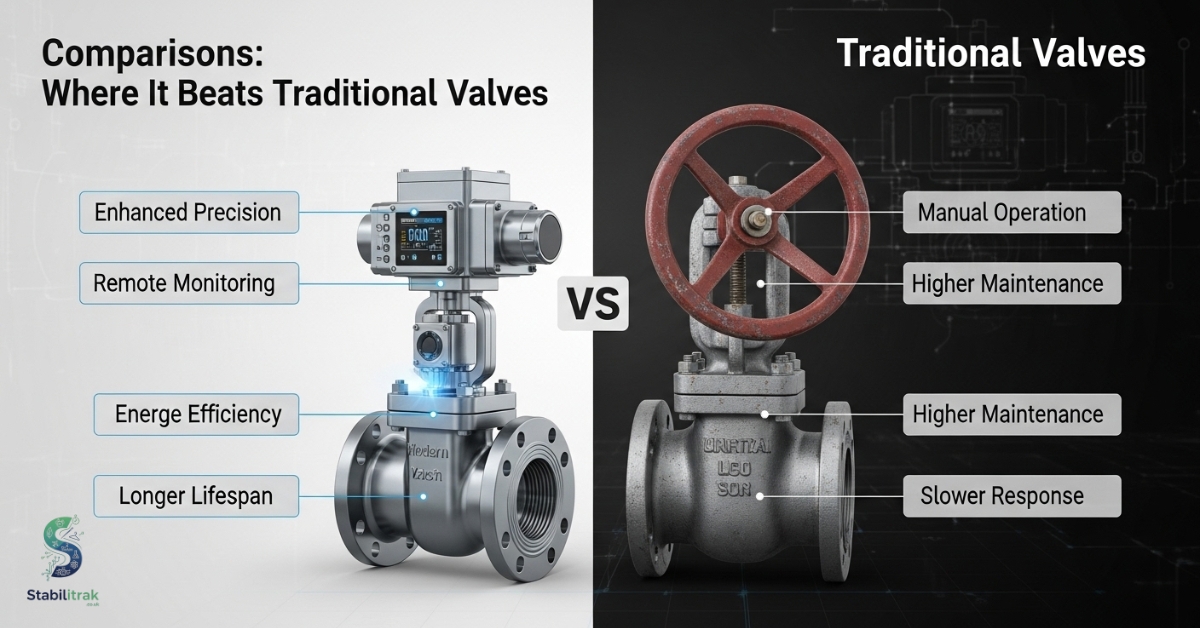

Comparisons: Where It Beats Traditional Valves

| Valve Type | Eccentric Hemispherical Strengths | Typical Weaknesses vs. Others |

| Ball Valve | Better wear resistance, less leakage with abrasive media | Higher cost, more complex seat machining |

| Butterfly Valve | Lower torque, faster open/close, lighter build | Less excellent sealing under high pressure or abrasion |

| Gate Valve | Excellent shut-off, simple structure | Heavy, slower operation, more maintenance, larger footprint |

Application Fields

Eccentric hemispherical valves serve best in severe service areas:

- Oil & Gas: handling crude, natural gas, or slurries with suspended solids, high pressure, sometimes corrosive or erosive compounds.

- Chemical & Petrochemical: acids, alkalis, polymers, and media where tight sealing and corrosion resistance are critical.

- Power Generation: steam, cooling water, ash slurry lines, conditions where high temperature, erosion, and pressure fluctuate.

- Mining / Mineral Processing: slurries, tailings, abrasive solids in fluid, i.e., applications where standard ball or gate valves wear rapidly.

- Water & Wastewater Treatment: sludge, fibrous media, sewage valves that clog, leak, or need frequent repair cost heavily.

Read More Article: How Many Kcal in a Slice of Pizza?

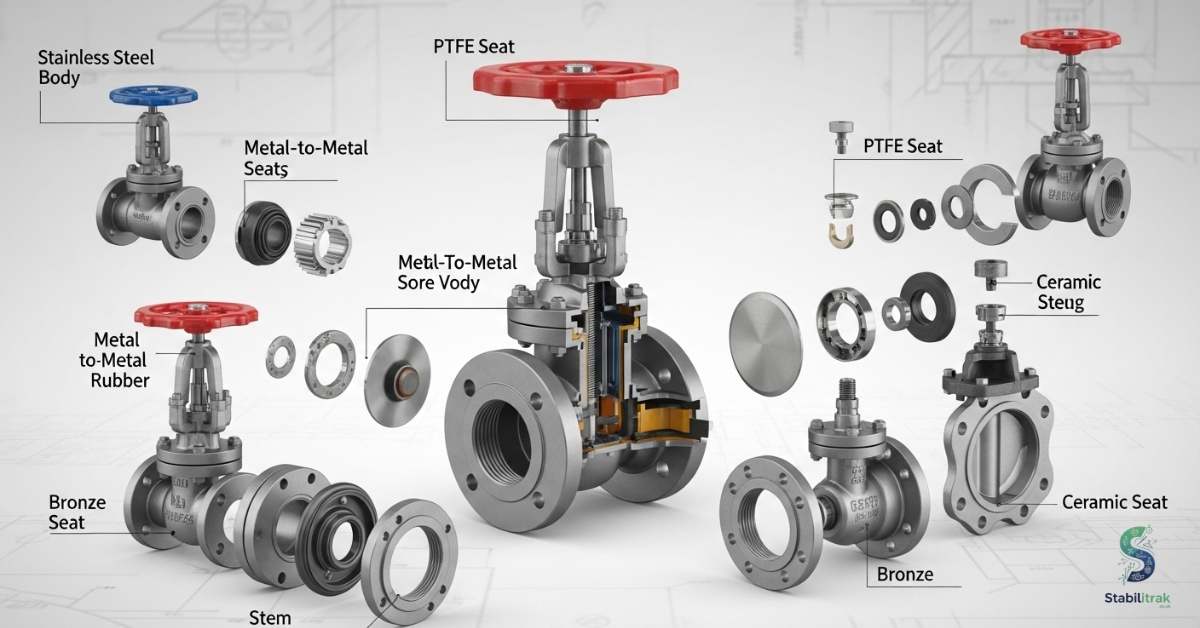

Material & Seat Considerations

Choosing appropriate materials is vital. The seat often uses tungsten carbide, hard-faced alloys, and alloy-coated metals to resist abrasion. Soft seals (e.g., PTFE, rubber) are available, but less durable in abrasive media. The body material might be stainless steel, carbon steel, or nickel-based alloys, depending on corrosion, temperature, and pressure.

Also, sealing design matters: metal-to-metal seats deliver durability, but require precise machining and alignment. Wedge seal or hard face contact designs improve seal under varying pressure differentials.

Design Variants & Mounting Options

There are several variations:

- Top-mounted actuators: easier maintenance, especially in pipelines where removing the valve is difficult.

- Side-mounted: better where space is limited, lighter weight.

- Double-eccentric designs: increase offset, further reduce wear, improve sealing under tough conditions.

- Self-cleaning sealing surfaces: some models allow the fluid to flush across seats (360° aspects) to wash off buildup.

Installation, Operation & Maintenance Tips

- Install with the correct orientation and support; ensure the direction of flow matches the valve markings.

- Before the operation, perform seat and leak tests under working pressure.

- Use actuators sized correctly; oversizing may cause sluggish response or damage.

- Maintenance intervals depend on media: abrasive or fibrous fluids require more frequent inspections. Clean the sealing surfaces, check stem packing, and lubricate moving parts.

- When you see leakage or seating wear, replace the sealing pair or seat rather than letting damage worsen.

Performance Specs to Watch For

- Pressure Rating: Valve ratings often go high (several MPa up to classes like ANSI 1500 or equivalent).

- Temperature Range: Many eccentric hemispherical valves handle from sub-zero to several hundred degrees Celsius, depending on materials.

- Operating Torque: Look for valves that require lower torque because eccentric designs reduce contact friction.

- Protection Standards / Certifications: ISO, API, CE, etc., depending on region or application.

Real-World Scenarios

Imagine a pipeline transporting slurry with 10 to 15% solid particles. A standard ball valve might wear out seat surfaces quickly. An eccentric hemispherical valve keeps smooth flow, minimal erosion, and near-zero leakage.

Or, in a chemical plant handling acid streams at 200°C and high pressure, using a valve with a corrosion-resistant alloy seat and precise sealing ensures safety and durability.

Limitations & Trade-Offs

- Higher initial cost: Machining the seat, using hard materials, precision alignment, and certification often increase upfront cost.

- Larger bodies or more complex designs may increase weight or need space.

- Soft-seal versions may leak or degrade faster under abrasive conditions.

- In very low-cost, clean fluid, low-pressure systems, using an eccentric hemispherical valve may be overkill compared to simpler ball or butterfly valves.

Conclusion

In short, what is an eccentric hemispherical valve? It’s a valve combining an offset, lifting motion with a hemispherical disc to deliver tight sealing, reduced wear, and efficient flow even under harsh service conditions. It outperforms standard valves, especially where function depends on durability, tight sealing, and handling challenging media.

If your system faces abrasive fluids, high pressure, or temperature cycles, or you hate dealing with frequent valve maintenance, this valve type could be your smart, long-term solution.

FAQS

What is an eccentric valve?

An eccentric valve is a valve where the disc or plug is offset from the centerline to reduce friction and improve sealing.

What is the difference between concentric and eccentric valves?

Concentric valves have the disc centered on the shaft, while eccentric valves have it offset for smoother operation and tighter sealing.

What is the use of an eccentric plug valve?

An eccentric plug valve is used to handle abrasive, corrosive, or high-pressure fluids with minimal wear and reliable shutoff.

What are the three types of valves?

The three main types of valves are gate valves, globe valves, and ball valves.

1 thought on “What Is an Eccentric Hemispherical Valve?”